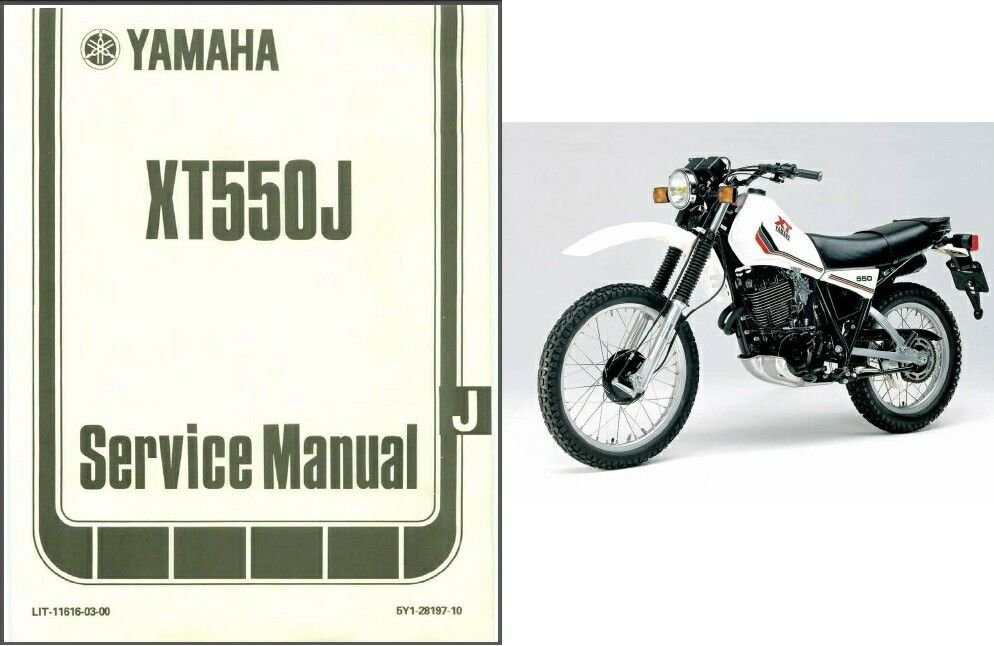

Yamaha Xt 550 Owners Manual

For those of you lucky people out there to own arguably the most superior motorcycle ever, I'm sure you have at one time wanted to find a safehaven where you can share your XT550 stories, what companies still make mod parts for this bike, what you can customize or swap from different bikes, and general information that may be somewhat hard to find without calling your local dealership or knowing somebody. Alteast I know I do!

So here is that thread, on this wonderful forum, for just that! I mean, it isn't fair the XT500 and XT600 have their own thread, right?! I'm going to keep the first post for informational purposes and reference so searching will be far easier. I've quite often tried to search for information on this bike and found it hard or impossible to find, so hopefully this will be your one stop information spot! Post up your stories and projects, whether it be just an OEM restoration or full custom! Also, don't hesitate to PM me information to update or post it in this thread!

The point is to share what you can to better the XT550 community! Well, I'll start off with my own XT550 project. This bike was received in barely road legal condition. The previous owner had been in a head on collision and used the money he received to fix the bike to just barely road legal condition. At first this was just going to be my bike for learning to ride on the road, and it quickly became my favorite project even though I did not have much money. I spent about $700 total to get the bike to road legal form and I still have a few more things I'd like to do. This year the bike gets some TLC and some swapped parts for road duty.

Link to project: Here are some pictures of before and after: Before: Midway: Currently. My mild mannered XT550 was a CL find in Memphis and sat in a dank u-rent it shed for several years. After some carb cleaning she was running mostly ok. From Arkansas Ozarks It didn't take long to figure out that my choice of riding was not its favorite thing to do. So let the metamorphis begin. Stinkbug mode.

I added a YZ465 shock. That raised the rear 4'.

From XT-Morph So I had to do something with the front, and I found a solution behind the local bike shop. I thought I'd picked up an old honda XR600, but after I got it home it was a bastardized XL350 with XR350 suspension. It was a real POS. But it gave me 41mm Showa forks and Disc brake. From XT-Morph With a little measuring and a visit to the local machine shop I had the front end mounted to the XT.

I also replaced the round light with a Baja Designs Halogen headlight. I also replaced the donkey dick Slip on muffler with the Keyway-Cobra USFS approved spark arrestor.

From XT-Morph Its a little noisey compared toe the slip on, but at least its forest legal now. I had expiramented with a Tenere conversion. I got an 8 gallon tank from XT600 but that moved the rider to far back and with the short 550 swingarm it was a tough to keep the front wheel on the ground. From XT-Morph So it came back off. I killed the 550 mill, well almost, I hypercooled the cylinder last summer and it started using oil, 1qt to 60 miles.

So since I had a second project a TT600 sitting there collecting dust. I decided to use that engine. So the XT550 is powered by the TT600 mill. I can say that the torque increase is awesome. Just crack the throttle it surges forward regardless of the hill. I had to rebuild the rear wheel, I had a cracked rim and several busted spokes. So a phone call to Buchannon Spokes and $120 lighter I had a set of stainless spokes and nipples.

I had an old Zuki TM250 chassis out back and guess what the hub was very close to the same diameter as the 550. So here we go, strip it down and lace up the new used wheel and make a visit to Bill at Conway Allsport for truing and all is good. My next issue is the fuel range. 3.1 gallons just doesn't quite cut it. I had an extra tank, I cut it open and went to work enlarging a stock tank. It is now at 5 gallons.

I've got a few leaks to fix yet, but the welding is 98% done. It is ugly, but I wasn't trying to win a beauty contest. From XT-Morph From XT-Morph Once its done, I will add a speedometer again, maybe an AceWell or a Trailtech vapor. I also need some better mirrors. It needs the TT600 carb put on it as the XT550 carb is to lean for a 600 mill with free flowing exhaust. Click to expand.The shock swap takes a little frame grinding. It is an external reseviour shock.

It has better fell than stock, but it also uses a heavier spring and the XT550 swingarm is shorter than the YZ part. Its 21/18 wheel size. Its an XR350 front end. The shim: From Now thats where it gets interesting. This allows use of the OEM lower XT550 bearing on the XR350 stem. The top bearing is actually the XR350 bearing in the XT550 race. I measured it and compared bearing height and how it set in the race, it fit just like it did in the XR frame.

So I figured lets try it. No faults yet from it. I abuse my poor bike. If I decide to go, it goes.

Rocks, mud, you name it. Two things I havn't done yet that it needs: I need to replace the chain guide. It also needs a spring loaded roller added under the chain it will jump a tooth once in a while when rear suspension is unloaded, like trying to work out of the mud or something. With the extreme angle of the swingarm you have to run the chain very very loose when unloaded to keep from killing the chain or rear bearings or the countershaft. I don't think twice about much like this old Logging road. From Safteyfifth wasn't happy about it when we wandered into it though on his KLR.

One more picture. Rock ledge beside the North Illinios Bayou, North of Hector Arkansas. Plus it shows the ADV sticker. From 10-31-09. Sorry - no pix, but when I was in college (1992) I got a 1981 xt550 to get around on. Worked all summer to pay the $1000.

My parents always hated bikes so I was on my own - this was my 3rd that I worked for and got on my own. The XT cost me more than my 1st two combind! I rode the hell out of it for 10 years. It was one tuff SOB.

In 2002 I killed it and replaced it with a 99 LC4 640e - another big ol street leagal dirt bike. Saw a pix of the old the XT in a stack of college photos and it took me back to a very fun time in life. Took my wife for a ride on it before we even started dating. Put a milk crate on the back and loaded it up with camping gear. I graduated on saturday and hauled it down to FL sunday to start work on monday.

I fit everything I owned - including the XT in my car and on 4x8 flat bed former pop up frame. The pix I found was of it all loaded up and ready to leave college. I know long but that bike was special to us.

GENERALEXCLUSIONS from this warranty shall include any failures caused by: a. Competition or racing use. Installation of parts or accessories that are not qualitatively equivalent to genuine Yamaha parts. Abnormal strain, neglect, or abuse. Lack of proper maintenance. Accident or collision damage. Modification to original parts.

Damage due to improper transportation. SPECIFIC EXCLUSIONS from this warranty shall include parts replaced due to normal wear or routine maintenance. THE CUSTOMER’S RESPONSIBILITY under this warranty shall be to: 1.

Operate and maintain the motorcycle as specified in the appropriate Owner’s Manual. Give notice to an authorized Yamaha motorcycle dealer of any and all apparent defects within ten (10) days after discovery, and make the machine available at that time for inspection and repairs at such dealer’s place of business. You may locate your nearest authorized Yamaha dealer through your local telephone directory. WARRANTY TRANSFER: To transfer any remaining warranty from the original purchaser to any subsequent purchaser, it is imperative that the machine be inspected and registered for warranty by an authorized Yamaha motorcycle dealer.

In order for this warranty to remain in effect, this inspection and registration must take place within ten (10) days after transfer. Areasonable dealer imposed fee may be charged for the inspection. In no case will warranty be extended beyond the original period.

Yamaha Xt 500 Owners Manual

EMISSIONS CONTROLSYSTEM WARRANTY Yamaha Motor Corporation, U.S.A. Also warrants to the ultimate purchaser and each subsequent purchaser of each Yamaha motorcycle covered by this warranty with a displacement of 50cc or greater, that the vehicle is designed, built, and equipped so as to conform at the time of sale with all U.S.

Emissions standards applicable at the time of manufacture and that it is free from defects in materials and workmanship which would cause it not to meet these standards within the periods listed immediately below. Failures other than those resulting from defects in material or workmanship which arise solely as a result of owner abuse and/or lack of proper maintenance are not covered by this warranty. Incoming search terms:.

To install this needle and jet kit:. Remove carburetors from the engine per Yamaha shop manual procedures. Note: Always perform internal carburetor work in a clean area.

Remove the vacuum slide from each carburetor. Remove the OEM needle, spacer and washers, noting order of assembly. (Note; the washers are used as shims to raise the needle, each is equivalent to ½ clip position, use these to fine tune the needle). Counting from the top to the bottom, install the new Baron needle clip on groove #4 of the replacement Baron adjustable needles. The top is the blunt end of the needle. Reinstall the OEM spacer and washers as shown in the figure below.

Reinstall the vacuum slides along with the diaphragm spring and reattach the diaphragm covers Note: Verify that the slides maintain their full range of movement!. Drain the fuel from the float bowls and remove the bowl covers. Remove the OEM main jets and replace them with Baron’s supplied Mikuni main jets. Install the “base setting” main jets as indicated above.

NOTE: V-Star 1100 carburetion runs staggered jetting! Make sure the front cylinder’s carburetor gets the larger main jet (numerically), and the rear cylinder’s carburetor gets the smaller main jet.

Extra jets have been included in your kit. These will help you fine-tune the carburetors for changing conditions. These conditions include climate and weather patterns in your area as well as exhaust equipment on your motorcycle. Barons determines the jet and clip recommendations that best suit your average riding conditions based upon information supplied to us at the time of your order. Changes in weather, altitude or modifications to your exhaust system may require jets other than those supplied. Thoroughly clean the inside of the float bowls prior to reinstalling them.

311 #1 Industrial Way – Fallbrook, CA 92028 – USA Phone: (760) 731-1200 Fax: (760) 731-1284 E-mail: tech@baronscustom.com Website: www.baronscustom.com Included in this kit: (4)Mikuni main jets #107.5, 110, 112.5, 115, (2) titanium needles, (2) clips, (8) cap-head allen screws Tools required: 3-4-5 mm allen wrenches, 10&12 mm sockets, 10mm end wrench, phillips & flat screwdrivers, pliers, drill. Revision 4.0.

Reassemble the carburetors by reversing the order of above steps. Use the new supplied cap head Allen screws in place of the OEM Phillips head screws for the float bowls. Locate the fuel mixture screws – they will either be a screw head or a brass plug. If it is a screw head, skip to step c. If you see a brass plug with a small hole in the center, proceed as follows: a. With a 5/32″ drill bit, carefully and slowly drill through the fuel mixture plugs.

Disconnect Battery 2. Lift and secure bike 3. Remove brake-side floorboard 4. Remove exhaust. Remove rear fender 6. Remove front pulley cover 7.

Remove wheel, pulley, and brake assembly simultaneously. Now remove front pulley from transmission. (Keep up with the stock nut and lock washer; these will be used during assembly) 8. Remove Passenger pegs; now remove the plastic covers in the frame that cover the pivot tube bolts.

Remove the stock shock bolts ( keep for re-assembly) 10. Remove the pivot tube bolts. Remove the stock swingarmb12. Install “new” belt at this time. Install supplied pivot tube, and bearings in RC swingarm. Install shock bolt with red loctite in RC swingarm.

(Do not tighten bolt at this time) 15. Insert supplied pivot bolts with red loctite through frame and supplied bushings into the RC swingarm. (Right side bushing has flats) 16. Torque shock and pivot bolts to factory specs. Install belt adjustment bolts and single side keys into swingarm. Remove any aftermarket accessories (saddle bags, back rests, etc) before hitch installation.

After installation remount accessories. NOTE: Some aftermarket accessories may not be compatible with InstaTrike hitch.

1) Place motorcycle on a smooth level surface on center stand. 2) Attach Bracket A (left) to outside of rear passenger foot peg mount. Place spacers between Bracket A and foot peg mount. Use new bolts provided. 3) Attach Bracket B (right) to outside of rear passenger foot peg. Place spacers between Bracket B and foot peg mount. Use new bolts provided.

Bracket will extend over top of mufflers. 4) Attach Brackets C (left) and D (right) to rear frame bolts on motorcycle. Located near rear turn signals Use new bolts provided. (10M x 25mm long) It may be necessary to loosen or remove backrest covers or hardware in order to easily access rear frame bolts. After Bracket C and D installation, reattach and/or tighten backrest mounts. 5) Attach Bracket E(left) / F(right) to bottom of Brackets A & B and to the TOP of the forward hitch arms. Ensure hitch is square on motorcycle and snug bolts for Brackets A, B, and E,F at this time.

6) Raise rear of hitch so bottom of Brackets C & D are flush with top of rear hitch plate. Ensuring that hitch is square with motorcycle, carefully mark hole locations for bottom of Brackets C&D on rear hitch plate. Drill rear hitch plate holes with 3/8 inch drill. This step ensures proper alignment and spacing of hitch on the motorcycle. 7) Tighten all bolts ensuring that hitch is square on motorcycle. Periodically check bolts for tightness.

Bracket Identification INSTALLATION OF THE TOW-PAC HITCH CART. Place your motorcycle on a smooth flat surface, like a garage floor, and rest it on its center stand. Assemble the axles, tires and wheels, and fenders onto the tow- pac hitch cart. Carefully align the tow-pac hitch cart’s hitch mount with the receiver hitch on the motorcycle. Now push the hitch mount into the receiver hitch. (this might be a little difficult until you get use to doing it.

Removing the paint from the hitch mount and applying a little grease will help.) 4. Place the hitch pin through the receiver hitch and hitch mount ( alignment plate ). Install and tighten the tension bo Incoming search terms:. The nitrous bottle is an aluminum cylinder designed and manufactured to withstand very high internal pressures. The valve on top of the bottle is a high-flow design that allows easy opening and closing which controls the nitrous flow to the engine compartment. Accurate calibration of your nitrous system depends on the bottle remaining at a stable temperature. In vehicles where the bottle must be mounted in an area subject to direct sunlight, it is suggested that the bottle be shielded with a bottle blanket when not in use.

Here is the performer bottle valve. Installed on all bottle valves used in Edelbrock Nitrous Systems is a pressure relief device or “PRD”. It is a safety device designed to vent the contents of the bottle into the atmosphere if over-pressurization occurs. Unsafe bottle pressure is caused by over filling or elevated bottle temperatures. It is illegal to tamper with or remove the pressure relief device! Bottle Safety Information 1.

Do not attempt to remove the bottle valve. Please return your bottle to Edelbrock if service is required to the siphon tube or the bottle valve itself. Never heat the outside of your nitrous bottle with an open flame such as a torch. Do not strike the surface of your nitrous bottle with a heavy or sharp object. Do not drop your nitrous bottle.

Do not attempt to grind off or destroy any imprinted markings on the face of the bottle. Do not remove, modify or otherwise tamper with the pressure relief device on the bottle valve. Do not attempt to use a bottle that has been damaged or tampered with.

Remove and retain the (4) chrome caps from the handlebar clamps. Remove and retain the (4) stock allen head bolts. This hardware will be re-used with the new Billet Tach Mount Kit. Carefully remove the stock handlebar clamps while supporting the handlebars.

INSTALLATION: 2. Slide the Electronic Tachometer (#6) into the Billet Tach Mount (#2) and secure with the 10-24 X 1/4″ Socket Set Screw (#10) supplied. Carefully pull the tachometer wire harness through the larger hole in the Billet Tach Cup (#3) and secure the Billet Tach Cup with the 10-24 X 1/8″ Socket Set Screw supplied. (The additional holes in the tach cup are for air circulation). Attach the Billet Tach Mount to the Billet Handlebar Clamp (#1) with the two 10-24 X 1-3/4″ Socket Head Screws (#4) supplied. Install the Billet Tach Mount assembly with the four stock allen head bolts and chrome caps removed in step 1 above. Adjust handlebars to desired height and torque bolts to factory specs.

WIRING INSTRUCTIONS: 3. Refer to FIG. Disconnect negative cable from battery. Remove fuel tank retaining bolts. Raise fuel tank about 3″-4″ to expose the Left Side Ignition Coil. It is not necessary to completely remove the gas tank on the Road Star. (V-Star 1100 applications use the right front coil and require fuel tank removal.) TIP: Long needle nose pliers are useful in removing and re-installing the coil wires.

If desired, tach wire loom may be shortened as necessary. Using an appropriate crimping tool, connect the Tachometer wires in the following manner: Cut Shrink Tubing (#9) into two 1″ pieces. The actuator spool is installed in the CIU housing with the actuator cable. The actuator spool is rotated to fully extend the cable. The carburettor cable and spool are installed and the other end of the carburettor cable is attached to the carburettors. Note the position of the roll pin. It is nearly contacting the end of the groove in the actuator spool.

The free play in the carburettor cable must be adjusted so that the cable outer can be pulled out 2 3mm before the carburettors start to open. This ensures that the cruise control cannot prevent the carburettors returning to idle. If more free play is allowed the response of the cruise control is compromised. This adjustment of free play is usually performed after final assembly of the CIU is completed and the CIU is in its final location. This is because flexing the cable does effect the free play. It is shown at this stage in these diagrams to improve clarity. After this adjustment is performed, the carburettor cable adjustment MUST NOT BE MOVED.

All future adjustments of free play in the throttle must be performed on the throttle cable from the throttle grip. If incorrect free play in this cable is suspected due to inconsistent cruise operation or because of inconsistent idle speed, the adjusters on the throttle cable from the hand grip must be backed all the way off to give as much free play as possible.

If this does not result in AT LEAST 5mm of free play in the throttle cable, the throttle cable must be removed from the hand grip or CIU before adjustment of the carburettor cable is attempted. This is crucial because the amount of free play in the throttle cable also effects the apparent free play in the carburettor cable.

The actuator spool is installed in the CIU housing with the actuator cable. The actuator spool is rotated to fully extend the cable. The dual spool and carburettor cable are installed. The carburettor cable is attached to the lower groove in the dual spool.

The other end of the carburettor cable is attached to the carburettors. Note the position of the roll pin. It is nearly contacting the end of the groove in the actuator spool. The free play in the carburettor cable must be adjusted so that the cable outer can be pulled out 2 3mm before the carburettors start to open. This ensures that the cruise control cannot prevent the carburettors returning to idle. If more free play is allowed the response of the cruise control is compromised.

This adjustment of free play is usually performed after final assembly of the CIU is completed and the CIU is in its final location. This is because flexing the cable affects the free play. It is shown at this stage in these diagrams to improve clarity. After this adjustment is performed, the carburettor cable adjustment MUST NOT BE MOVED.

All future adjustments of free play in the throttle must be performed on the throttle cable from the throttle grip. If incorrect free play in the carburettor cable is suspected due to inconsistent cruise operation or because of inconsistent idle speed, the adjusters on the throttle cable from the hand grip must be backed all the way off to give as much free play as possible. If this does not result in AT LEAST 5mm of free play in the throttle cable, the throttle cable must be removed from the hand grip or CIU before adjustment of the carburettor cable is attempted. This is crucial because the amount of free play in the throttle cable also affects the apparent free play in the carburettor cable.